Powder Coat Production Line for Chimney Hoods

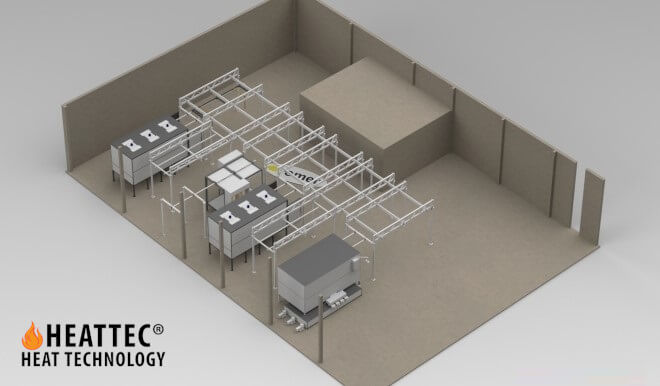

We have successfully installed and operationalized an advanced powder coating production line for chimney caps at our customer in Ittervoort, the Netherlands. This extensive production line includes several essential components that together ensure efficient and high-quality production.

A crucial part of this production line is the muffle furnace, which plays an essential role in the curing process of the powder coating material on the chimney caps. This oven has been carefully integrated to ensure optimal results and meets the highest industry standards.

In addition, we have integrated a special drying oven into the production line, which ensures that the coated chimney caps are thoroughly dried before further processing. This contributes to the durability and quality of the end product, ensuring that it meets the strictest quality standards.

The powder booth with associated filter unit is another essential part of the production line. This booth provides a controlled environment for applying the powder coating material to the chimney caps, while the filter unit ensures that harmful particles are captured and the air is purified. This not only results in an environmentally friendly working environment, but also in a high-quality finish of the products.

To make the entire production process seamless, we have integrated an advanced transport system. This system ensures an efficient flow of the chimney caps through the different stations of the production line, maximizing productivity and minimizing lead time.

In collaboration with our customer, we have ensured that this powder coating production line not only meets the specific requirements of the chimney cap industry, but also the highest standards of efficiency, quality and environmental friendliness. The successful installation and commissioning of this production line illustrates our ability to provide tailor-made solutions that meet the unique needs of our valued customers.